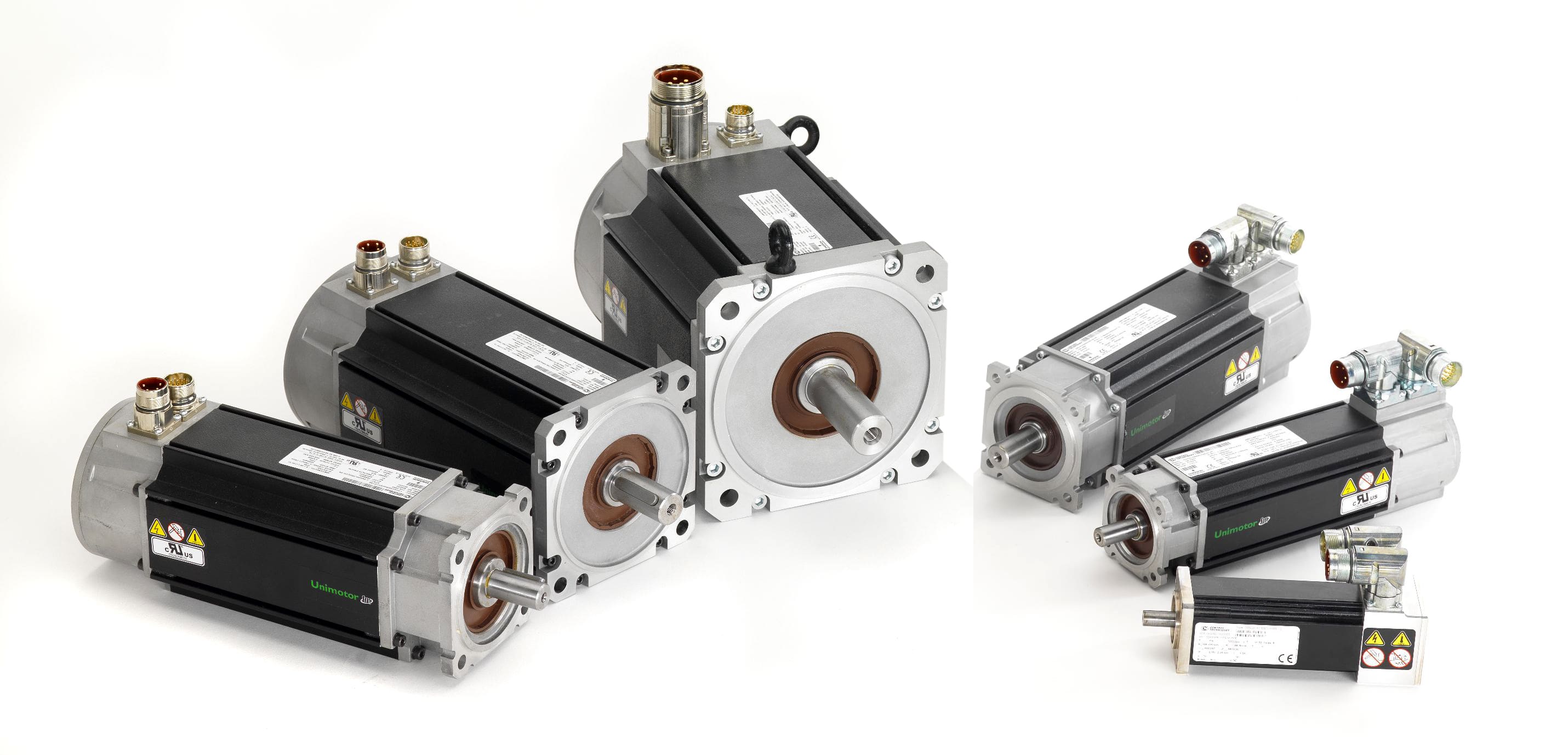

Industrial motors are a critical component of modern manufacturing and automation, powering machinery and processes across a variety of industries. These motors are designed for heavy-duty use, providing the necessary mechanical energy to drive equipment such as conveyor belts, pumps, fans, compressors, machine tools, and other large-scale industrial systems. They convert electrical energy into mechanical motion, facilitating the functioning of various industrial operations.

Types of Industrial Motors :

AC Motors (Alternating Current Motors) :

- Synchronous Motors: Operate at a constant speed, synchronized with the frequency of the current. Often used in applications that require precise speed control.

- Induction Motors: The most common type of industrial motor, relying on electromagnetic induction. Known for their durability, simplicity, and relatively low maintenance. Suitable for applications such as pumps, fans, and conveyor systems.

DC Motors (Direct Current Motors) :

- Used where precise speed control is essential. They are often found in applications like electric vehicles, elevators, and machinery with variable speeds.

- Shunt, Series, and Compound Motors: Different winding configurations offer varying levels of torque and speed control.

Servo Motors: :

- Used in applications requiring high precision and control, such as CNC machines, robotics, and automation systems. Servo motors can be either AC or DC and are highly responsive with feedback systems for positioning.

Stepper Motors: :

- Known for precise movement control, stepper motors move in discrete steps. They are widely used in CNC machinery, 3D printers, and positioning systems.

Service Features

-

Reasonable repair charges

-

24/7 call-out service

-

Fast turnaround

-

In-house repair service

-

Rush repair service

-

Spares available